DSG Corrado Project Update

Since our project introduction post, we have been receiving emails daily about when the DSG Adapter will be released. We are really enjoying hearing about all the project ideas and race car builds! The truth is, the DSG Adapter has been made for this project, so we have to get this car built to be able to test the controller. Progress is slow but nevertheless moving forward, this is a complete car build so there is a lot of care to be taken as to not have to re-do anything down the road and waste ever so precious time.

What I do have for you today though is a lot of pictures and some cool updates on the car. Working with Jay, we have decided to move forward with some of the assembly on the car. Initially the plan was to just come to our space for some wiring mock up and parts test fitting, but that plan has changed to get the car running! Once we can test fire the engine, we can see if our cool new DSG Adapter works as its designed to

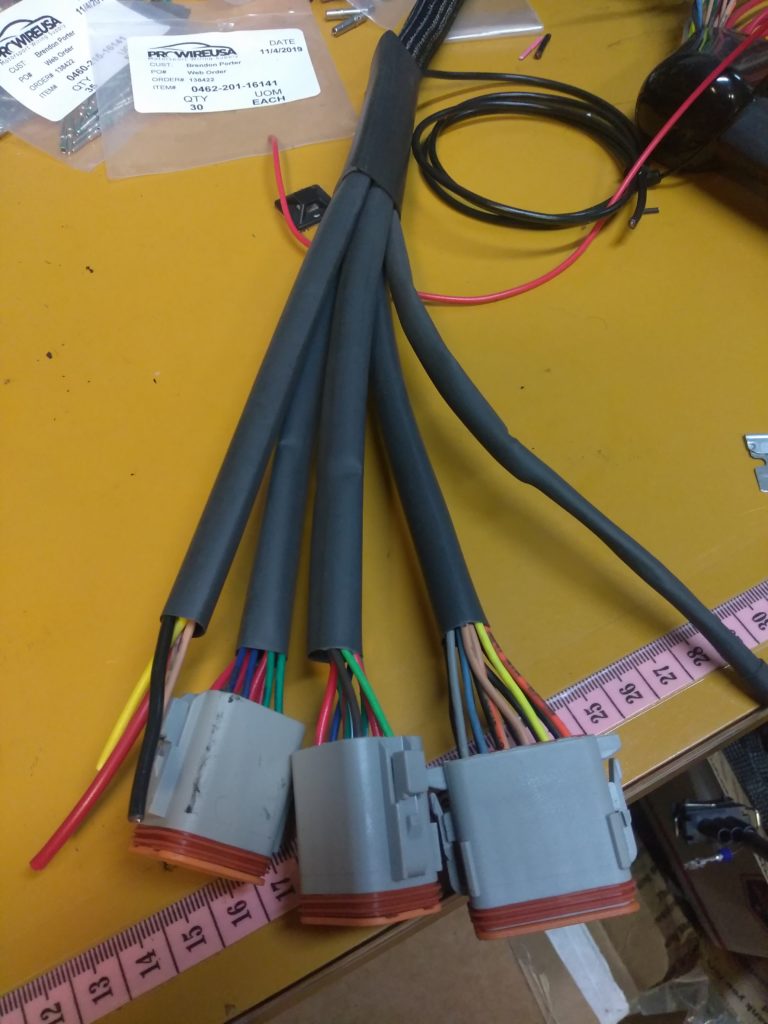

With some parts swapping to our ABA bottom end, we mated the factory vw DSG flywheel to the engine, installed the correct pilot bearing in the crank, and bolted the transmission to the engine. At the time, we did not have the cylinder head back from the machine shop, so we installed the block and transmission into our VW Corrado chassis. Using custom mounts from JRM Fabrication (these will be available on our website soon!), installation was simple with a engine hoist. With all the engine mounts installed, we could move on to installing the cylinder head and intake manifold to mock up our new wiring harness. Jay purchased one of our prototype modular harness kits for his Megasquirt 3 ECU. When paired with our DSG Adapter and our favorite PDM, this car will be reliable, simple to maintain and troubleshoot, and last for years to come. We tucked the ECU in the glove box and used a Deutsch HDP20 bulkhead connector to mate to the engine bay wiring harness. Installation time is reduced by using the bulkhead fitting, and will also allow for easy removal if required in the future. Jay has a lot of future upgrades plans, so ease of service is definitely a key feature.

With the engine in the bay and the manifolds in place, we were able to measure and build our wiring harness’. We also installed the radiator to test clearance for alternator, power steering lines and radiator fans. We were also able to design the cooling system as there are several stock components relocated, removed, or added to the system. For the time being, we are not installing the engine oil cooler and will be using the stock DSG heat exchanger. We looped the DSG exchanger in with our new 16v setup using a combination of OEM hoses and stock cooling system components. The goal for this portion of the build is street car reliability. We are using all new hoses and plastic cooling pieces, new OEM sensors and new radiator. This will make the car able to deal with daily driving as well as spirited cruises in the PNW.

3 Comments

Connell Siddons

This is great to see!!! I sense a rather significant upgrade to my race car next winter!

Steve Du Toit

Hi

How far is your DSG adaptor in testing and when will it be for sale to customers.

Regards

Roman Albrecht

Guten Tag wann kann man den dsg Adapter kaufen? Gruß